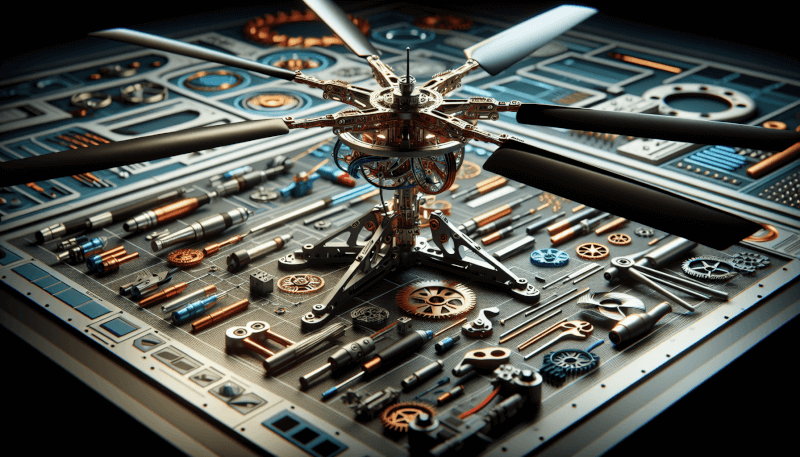

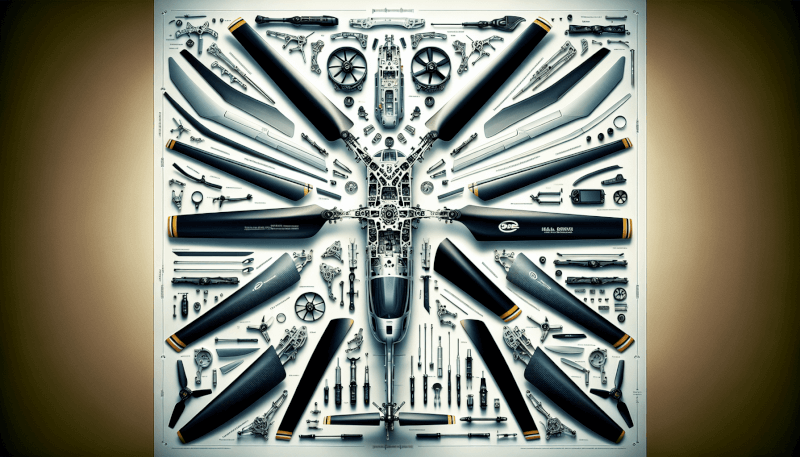

In the world of remote-controlled helicopters, the type of blades you choose can make all the difference in your flying experience. From the classic fixed-pitch blades to the more advanced collective-pitch blades, each type offers unique characteristics that can affect maneuverability, stability, and overall performance. Whether you’re a seasoned pilot or just starting out, understanding the various RC helicopter blade types is essential to finding the perfect fit for your flying style.

Main Rotor Blade

Design and Function

The main rotor blade is a crucial component of an RC helicopter as it is responsible for generating lift and controlling the overall flight characteristics of the aircraft. The design of the main rotor blade is carefully engineered to optimize its performance in various flight conditions. The shape and size of the blade, as well as the materials used, greatly influence its effectiveness.

Material

Main rotor blades can be made from a variety of materials, each with its own unique set of properties. Some common materials used include carbon fiber, wood, and plastic. The choice of material depends on factors such as weight, durability, and cost. Carbon fiber blades, for example, are lightweight and provide excellent stiffness, making them ideal for high-performance helicopters. Wooden blades, on the other hand, offer a more traditional aesthetic and are known for their durability.

Shape and Size

The shape and size of the main rotor blades are critical in determining the helicopter’s flight characteristics and performance. The blade shape, often referred to as the airfoil, affects how the blade interacts with the air and generates lift. Different airfoil shapes can produce varying amounts of lift, stability, and maneuverability. Similarly, the size of the blades affects the amount of lift generated, with larger blades typically generating more lift and smaller blades offering increased maneuverability.

Tail Rotor Blade

Purpose

The tail rotor blade serves a crucial role in an RC helicopter by counteracting the torque produced by the main rotor. Its main purpose is to provide rotational control and stability to the helicopter. By generating a sideways thrust, the tail rotor blade counters the rotational force produced by the main rotor, allowing the helicopter to maintain its heading and prevent uncontrollable spins.

Design and Function

Tail rotor blades are designed to be smaller and narrower compared to the main rotor blades. This design allows for efficient control of the helicopter without interfering with the airflow produced by the main rotor. The angle of attack and pitch of the tail rotor blades can be adjusted to optimize the helicopter’s stability and response. The tail rotor blade typically operates at a high RPM (rotations per minute) and must be made from materials that can withstand the stress and strain of rotating at such speeds.

Material

Tail rotor blades are commonly made from lightweight materials such as carbon fiber or plastic. These materials offer the necessary strength and durability to withstand the high rotational speeds while maintaining their shape and performance. Plastic blades are known for their affordability and ease of replacement, while carbon fiber blades provide superior stiffness and precision.

Flybar Paddle

Use and Function

The flybar paddle is a critical part of the helicopter’s stability and control system. It works in conjunction with the main rotor blades to provide stability and improve the responsiveness of the helicopter during flight. The flybar paddle is connected to the flybar, which acts as a stabilizer, helping to counteract sudden movements and maintain the helicopter’s balance.

Design and Material

Flybar paddles are typically designed with a symmetrical airfoil shape to ensure equal lift distribution during flight. This design allows for precise control and maneuverability. These paddles are often made from lightweight materials like carbon fiber, which provides the necessary strength and stiffness for optimal performance.

Adjustments

The flybar paddle can be adjusted to customize the helicopter’s flight characteristics. By changing the angle of attack of the paddle or adjusting its weight distribution, you can fine-tune the responsiveness and stability of the helicopter. These adjustments allow pilots to tailor their aircraft to their flying style and preferences.

Carbon Fiber Blades

Benefits

Carbon fiber blades offer several advantages over other materials. One of the key benefits is their lightweight nature, which reduces the overall weight of the helicopter and improves its maneuverability. Additionally, carbon fiber blades possess excellent stiffness, allowing for precise control and minimal flex during flight. This stiffness contributes to increased responsiveness and better aerodynamic performance.

Drawbacks

While carbon fiber blades provide numerous benefits, there are also some drawbacks to consider. Carbon fiber blades tend to be more expensive compared to other materials, which can be a deterrent for some hobbyists. Additionally, carbon fiber blades are more prone to damage from impact or rough landings. Although they offer excellent stiffness, they can be more brittle than other materials, making them more susceptible to cracking or breaking.

Suitable Applications

Carbon fiber blades are best suited for high-performance helicopters and competitive racing. Their lightweight nature and exceptional stiffness make them ideal for swift maneuvers and agile flight. These blades excel in demanding flight conditions where precision and responsiveness are of utmost importance.

Wooden Blades

Advantages

Wooden blades have their own set of advantages that make them popular among RC helicopter enthusiasts. One of the main advantages of wooden blades is their exceptional durability. Wood can handle impact and vibrations well, making it less susceptible to damage compared to other materials. Wooden blades are also known for their classic aesthetic appeal, adding a touch of nostalgia to the helicopter’s overall design.

Disadvantages

The primary disadvantage of wooden blades is their weight. Wooden blades tend to be heavier than other options, which can affect the helicopter’s maneuverability and overall performance. Additionally, wooden blades can absorb moisture over time, causing them to warp or deteriorate. This moisture absorption can negatively impact the blade’s balance and flight characteristics.

Recommended Usage

Wooden blades are suitable for recreational flying and casual flights. They are an excellent choice for beginners or pilots who prioritize durability and a traditional aesthetic. Wooden blades are often used in scale models or vintage-style helicopters, enhancing their visual appeal while providing satisfactory performance for less demanding flying scenarios.

Plastic Blades

Features

Plastic blades offer several notable features that make them a popular choice for RC helicopter enthusiasts. One of the key features is their affordability, making them budget-friendly options for hobbyists. Plastic blades are also known for their flexibility, which allows them to absorb impact and vibrations without breaking. This flexibility can be advantageous for beginners learning to fly or for less aggressive flying styles.

Pros and Cons

One of the significant advantages of plastic blades is their low cost, making them accessible to a wide range of hobbyists. Additionally, plastic blades are less prone to cracking or breaking, making them durable options for beginners or those operating in rough flying conditions. However, plastic blades typically offer less stiffness and precision compared to other materials, which can affect the overall control and responsiveness of the helicopter.

Ideal Conditions for Use

Plastic blades are best suited for leisurely flights or beginner pilots who are still developing their flying skills. These blades can handle minor impacts and provide a forgiving flight experience. Plastic blades are commonly used for indoor flying or in less demanding outdoor scenarios where durability and cost-effectiveness are prioritized over high-performance capabilities.

Symmetrical Blades

Characteristics

Symmetrical blades are named as such because their airfoil shape is identical when viewed from the top or bottom. Unlike asymmetrical blades, which have a distinct convex or concave shape, symmetrical blades offer a balanced lift distribution. This balanced lift allows for more predictable flight characteristics and makes these blades suitable for various maneuvers and flight orientations.

Benefits and Limitations

One of the main benefits of symmetrical blades is their versatility. These blades perform consistently whether flying upright, inverted, or during aerobatic maneuvers. This versatility makes them suitable for pilots who enjoy experimenting with different flight styles. However, one limitation of symmetrical blades is their reduced lift generation compared to asymmetrical blades. They may require higher RPMs or larger blade sizes to generate the same amount of lift.

Best Applications

Symmetrical blades are commonly used in 3D helicopters or for pilots who enjoy aerobatic flying. Their predictable flight characteristics make them ideal for executing advanced maneuvers such as flips, rolls, and inverted flight. Additionally, these blades are often favored by pilots who prefer a more responsive and agile flying experience.

Semi-Symmetrical Blades

Design Principles

Semi-symmetrical blades are a hybrid design that combines elements of symmetrical and asymmetrical blade shapes. The airfoil shape of semi-symmetrical blades combines a flat bottom surface with a curved top surface. This design allows for a balance between lift generation and aerodynamic performance, providing a compromise between the characteristics of symmetrical and asymmetrical blades.

Flight Performance

Semi-symmetrical blades offer a good balance between stability and maneuverability. These blades generate more lift than symmetrical blades while providing increased responsiveness compared to fully asymmetrical blades. The combination of lift and agility makes semi-symmetrical blades suitable for precision flying and aerobatic maneuvers.

Suitability

Semi-symmetrical blades are well-suited for intermediate to advanced pilots who seek a versatile blade profile. These blades are often used in helicopter models designed for sport flying or precision aerobatics. Their well-rounded performance characteristics make them capable of handling a wide range of flight styles and maneuvers.

Airfoil Blades

Working Principles

Airfoil blades are designed with a specific shape known as an airfoil. This shape allows for efficient lift generation by utilizing the Bernoulli’s principle of fluid dynamics. The airfoil shape, which is curved on the top surface and flat on the bottom, creates a pressure difference, resulting in upward lift. The angle of attack, or the angle between the blade’s chord line and the airflow, also affects the lift generation.

Benefits and Trade-offs

Airfoil blades offer several benefits that contribute to their widespread use in RC helicopters. One of the main benefits is their ability to generate high lift coefficients, resulting in greater overall lift. This allows for improved payload capacity and better performance in demanding flight scenarios. However, airfoil blades often come with higher drag coefficients, which can impact the helicopter’s top speed and overall efficiency.

Application Considerations

Airfoil blades are commonly used in scale models, cargo or heavy lift helicopters, and applications where high lift capacity is required. These blades excel in scenarios where stability and lift are essential, such as aerial photography or search and rescue operations. Pilots who prioritize functionality and payload capabilities often opt for airfoil blades to meet their specific requirements.

Mixing Blades

Purpose

Mixing blades are a unique type of rotor blade designed to enhance the helicopter’s control and stability during flight. These blades are typically found in helicopters with swashplate-controlled rotor systems. Mixing blades work in tandem with cyclic and collective inputs to ensure proper pitch and roll control, ultimately influencing the helicopter’s flight performance.

Design Variations

Mixing blades come in different designs, depending on the specific helicopter model and intended flight characteristics. Some mixing blades feature a symmetrical airfoil shape, while others may have a semi-symmetrical or asymmetrical design. The choice of mixing blade design is influenced by factors such as the helicopter’s intended usage, desired flight response, and pilot preferences.

Optimal Usage

Mixing blades are best utilized in helicopters that require enhanced stability and precise control. These blades are often found in scale models, helicopters with complex aerobatic capabilities, or helicopters used for professional purposes such as filming or surveying. The addition of mixing blades allows for fine-tuned flight control, enabling pilots to execute complex maneuvers with greater precision and confidence.

In conclusion, understanding the various types of RC helicopter blades is essential for pilots and enthusiasts looking to optimize their aircraft’s performance. Each type of blade, from carbon fiber to plastic, offers unique characteristics and advantages for different flight scenarios. By considering factors such as material, shape, and intended usage, one can select the best rotor blade type to suit their flying style and achieve the desired flight experience. Whether it be for high-speed racing, precise maneuvers, or leisurely flights, the right choice of helicopter blade can greatly enhance the enjoyment and capabilities of remote control helicopter flying.