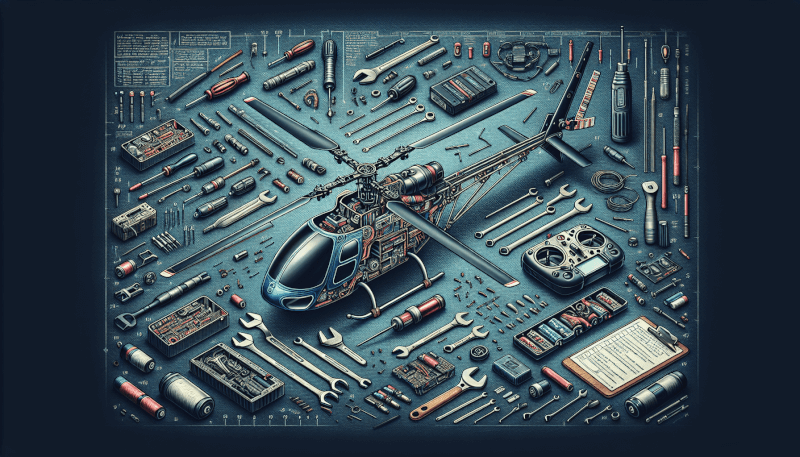

Maintaining your RC helicopter is essential to ensure it performs at its best and has a long lifespan. This comprehensive checklist will guide you through all the necessary steps to keep your RC helicopter in top condition, from inspecting the rotor blades to checking the battery and electronics. By following this easy-to-follow maintenance checklist, you can enjoy smooth and trouble-free flights every time you take your RC helicopter for a spin.

Pre-Flight Inspection

Inspect the Body

Before every flight, it is crucial to thoroughly inspect the body of your RC helicopter. Look for any visible cracks, dents, or signs of wear and tear. Pay attention to the landing skids, canopy, and other structural components. Any damage to the body can compromise the overall integrity of the helicopter and put your flight at risk. If you notice any issues, it is best to address them before taking off.

Check the Battery

The battery is the power source for your RC helicopter, so it is essential to check its condition before every flight. Start by inspecting the battery for any physical damage. Look for leaks, bloating, or deformed connectors. Next, check the voltage of the battery to ensure it is in the proper range. If the voltage is too low, it may indicate a need for charging or battery replacement. Finally, verify that the battery is securely connected to the helicopter and that the connectors are clean and free from dirt or debris.

Inspect the Blades

The blades of your RC helicopter play a crucial role in its stability and maneuverability. Conduct a thorough inspection of the blades before each flight. Look for any signs of cracks, chips, or warping. Even the slightest damage to the blades can have a significant impact on your helicopter’s performance. Additionally, ensure that the blades are securely attached to the rotor head and that there is no excessive play or looseness.

Check the Landing Gear

The landing gear of your RC helicopter is responsible for providing stability and shock absorption during takeoff and landing. Inspect the landing gear for any signs of damage, such as cracks or bends. Ensure that the screws or bolts securing the landing gear are tight and secure. It is also essential to check the landing gear for any dirt or debris that could hinder its functionality.

Examine the Transmitter

The transmitter is the control center of your RC helicopter, and it is crucial to ensure it is in optimal condition before each flight. Visually inspect the transmitter for any physical damage, such as cracks or loose buttons. Check that the antenna is straight and undamaged. Test the controls and switches to ensure they are functioning correctly. If your transmitter has batteries, make sure they are fully charged or replace them if necessary. A properly functioning transmitter is essential for safe and enjoyable flights.

Cleaning and Dusting

Remove Dust and Debris

Regular cleaning of your RC helicopter is important to maintain its performance and longevity. Start by removing any visible dust and debris from the body, rotor blades, landing gear, and electronics. Use a soft brush or cloth to gently clean the surfaces, being careful not to apply excessive force that could cause damage.

Use Compressed Air

Compressed air is an excellent tool for removing dust and debris from hard-to-reach areas of your RC helicopter, such as the motor or electronic components. Use a can of compressed air to blow away any accumulated dirt or particles. Ensure that the compressed air is directed away from sensitive areas and that it is used in short bursts to avoid causing damage.

Clean the Blades

The rotor blades of your RC helicopter can accumulate dirt, oil, or other debris during flights. Cleaning the blades regularly helps maintain their performance and ensures smooth operation. Use a soft cloth or cotton swab to gently wipe down the blades, removing any residue or buildup. If necessary, you can also use a mild cleaner or rubbing alcohol to remove stubborn dirt or grime. Be careful not to use any abrasive materials or excessive force that could damage the blades.

Clean the Transmitter

The transmitter is a critical component of your RC helicopter, and keeping it clean is essential for reliable control. Use a soft cloth or damp sponge to wipe down the transmitter’s surfaces, removing any dirt or smudges. Pay special attention to the buttons, switches, and knobs, ensuring that they are clean and free from any obstruction. Avoid using harsh chemicals or excessive moisture that could damage the transmitter.

Check and Clean Connectors

The connectors on your RC helicopter, such as those between the battery and the electronic components, can collect dirt or corrosion over time. Check all connectors for any signs of dirt or oxidation. Gently clean the connectors with a soft cloth or a specialized electrical contact cleaner. It is essential to ensure that the connectors are clean and firmly connected to maintain proper electrical connections.

Lubrication and Greasing

Lubricate Bearings

The bearings in your RC helicopter’s moving parts, such as the rotor head or tail rotor assembly, require proper lubrication to operate smoothly. Apply a small amount of lubricant specifically designed for RC helicopter bearings to each bearing. Use a specialized bearing oil or grease, following the manufacturer’s recommendations. Be careful not to over-lubricate, as excess lubricant can attract dirt or cause the bearings to malfunction.

Grease Gears and Moving Parts

To ensure smooth operation, it is important to grease the gears and other moving parts of your RC helicopter. Apply a thin layer of grease specifically designed for RC helicopters to the gears and other components that require lubrication. Avoid using excessive amounts of grease, as it can cause buildup and interfere with the proper functioning of the parts.

Inspect and Lubricate Rotor Head

The rotor head of your RC helicopter is responsible for controlling the movement of the main rotor blades. Regularly inspect the rotor head for any signs of wear or damage. If necessary, apply a small amount of lubricant to the moving parts of the rotor head to ensure smooth rotation. Be cautious not to use too much lubricant, as it can attract dust or interfere with the functionality of the rotor head.

Check Tail Rotor Assembly

The tail rotor assembly plays a crucial role in controlling the yaw movement of your RC helicopter. Inspect the tail rotor assembly for any signs of wear, damage, or loose parts. Apply a small amount of lubricant to the moving parts of the tail rotor assembly to ensure smooth rotation. Regular maintenance of the tail rotor assembly is essential to maintain stable flight characteristics.

Battery Maintenance

Check Battery Voltage

Before each flight, it is important to check the voltage of your RC helicopter’s battery. Use a voltmeter or a specialized battery checker to measure the voltage. Compare the voltage reading with the manufacturer’s recommended range. If the voltage is below the recommended range, it may indicate a need for charging or battery replacement.

Charge and Store Properly

Proper charging and storage practices are crucial for maintaining the longevity and performance of your RC helicopter battery. Follow the manufacturer’s instructions for charging your battery, ensuring that you use a compatible charger and the appropriate charging settings. After each flight, allow the battery to cool down before charging or storing. Store the battery in a cool, dry place, away from direct sunlight or extreme temperatures.

Inspect Wire Connections

The wire connections between the battery and the electronic components of your RC helicopter should be checked regularly for any signs of damage or looseness. Inspect the wires, connectors, and solder joints for any fraying, corrosion, or poor connections. Ensure that the connectors are securely plugged in and that there is no excessive play or movement.

Replace Damaged Cables

If you notice any damaged cables or wire connections, it is crucial to replace them immediately. Damaged cables can result in poor electrical connections or even complete failure during flight. Use high-quality replacement cables that are compatible with your RC helicopter’s specifications. Ensure that the replacement cables are properly insulated and securely connected to the electronic components.

Check Battery Health Indicators

Some RC helicopter batteries are equipped with built-in health indicators that provide information about the battery’s condition. Familiarize yourself with the specific health indicators of your battery and regularly check them. These indicators can provide valuable insights into the overall health and performance of your battery, giving you an indication if it needs to be replaced or serviced.

Motor and Electronics

Inspect Motor

The motor is the heart of your RC helicopter’s propulsion system, and it should be regularly inspected for any signs of wear or damage. Look for any loose connections, frayed wires, or physical damage to the motor. Ensure that the motor is securely mounted and that there is no excessive play or movement. Any issues with the motor can significantly impact the performance and flight capabilities of your RC helicopter.

Clean Motor if Needed

Dust, dirt, and debris can accumulate on the motor over time, reducing its efficiency and potentially causing overheating. If you notice any buildup on the motor, use a soft brush or compressed air to gently clean it. Be careful not to apply excessive force or use any liquids that could damage the motor or its components. A clean motor can operate more efficiently and help extend its lifespan.

Check Electronic Speed Controller

The electronic speed controller (ESC) is responsible for regulating the motor’s speed and power output. Regularly inspect the ESC for any signs of damage or loose connections. Ensure that the ESC is securely mounted and that there are no exposed wires or components. Additionally, check the programming of the ESC to ensure it is aligned with your flight preferences and skill level.

Inspect Wires and Connectors

The wires and connectors of your RC helicopter’s electronics should be regularly inspected for any signs of damage, looseness, or poor connections. Check all the wires, connectors, and solder joints for fraying, corrosion, or physical damage. Verify that all connections are secure and that there is no excessive play or movement. Properly functioning wires and connectors are essential for reliable electrical connections and performance.

Update Firmware if Applicable

If your RC helicopter’s electronics have firmware that can be updated, it is recommended to regularly check for any available updates. Firmware updates can address performance issues, add new features, or improve overall functionality. Follow the manufacturer’s instructions for updating the firmware, ensuring that you have a stable and reliable internet connection during the process.

Flight Control System

Calibrate Gyro and Accelerometer

The gyro and accelerometer of your RC helicopter’s flight control system are responsible for stability and orientation. Regular calibration of these sensors is critical for accurate flight control. Follow the manufacturer’s instructions to calibrate the gyro and accelerometer, ensuring that your RC helicopter is on a level surface during the calibration process. Proper calibration helps maintain stable flight characteristics and responsiveness.

Check Control Surface Movement

The control surfaces, such as the main rotor blades and the tail rotor, should be regularly checked for proper movement and alignment. Ensure that the control surfaces move freely and smoothly without any excessive play or binding. If necessary, adjust the linkages to achieve the optimal control surface movement. Properly aligned control surfaces are crucial for precise flight control and maneuverability.

Test Flight Modes

If your RC helicopter has multiple flight modes, it is important to periodically test each mode to ensure proper functionality. Switch between the different flight modes and observe how the helicopter responds. Verify that each mode engages correctly and that the flight characteristics match the selected mode. If you notice any discrepancies or irregularities, consult the user manual or contact the manufacturer for guidance.

Inspect Wiring and Connections

Inspecting the wiring and connections of your RC helicopter’s flight control system is essential to ensure reliable operation. Regularly check all the wires, connectors, and solder joints for any signs of damage, looseness, or poor connections. Ensure that the wiring is properly routed and secured to prevent interference or accidental disconnection. Properly functioning wiring and connections are crucial for accurate flight control and stability.

Update Firmware if Applicable

Similar to the electronics, it is recommended to regularly check for firmware updates for your RC helicopter’s flight control system. Firmware updates can enhance flight performance, improve stability, or introduce new features. Follow the manufacturer’s instructions for updating the firmware, ensuring that you have a stable and reliable internet connection during the process. Updating the firmware helps ensure that you have the latest advancements and optimizations for your flight control system.

Safety Checks

Check Emergency Stop

The emergency stop or kill switch is a critical safety feature of your RC helicopter. Test the emergency stop function before each flight to ensure it is functioning correctly. Activate the emergency stop and verify that the rotor blades stop spinning immediately. If the emergency stop fails, do not fly the helicopter until the issue is resolved. The emergency stop is an important safety measure in case of unexpected situations or loss of control.

Verify Fail-Safe Settings

The fail-safe settings of your RC helicopter’s flight control system are designed to automatically activate specific actions in the event of signal loss or interference. Regularly verify and test the fail-safe settings to ensure they are configured correctly. Fly your helicopter within range and test the fail-safe by turning off the transmitter. Observe how the fail-safe responds and ensure that it engages the desired actions, such as landing or hovering.

Inspect Safety Precautions

Inspect all safety precautions, such as fuselage markings, warning labels, and protective measures on your RC helicopter. These safety features are designed to protect you and others from potential harm. Ensure that all safety precautions are intact, easily visible, and legible. If any safety precautions are damaged or missing, replace them immediately. Safety should always be a top priority when operating an RC helicopter.

Check Home Point

If your RC helicopter has a return-to-home feature or GPS capability, it is important to regularly check the home point settings. The home point is the designated location where your helicopter returns in case of signal loss or upon activating the return-to-home function. Verify that the home point is set correctly and update it if necessary. Testing the return-to-home feature in a controlled environment can provide peace of mind in case of an emergency.

Perform Range Test

Before each flight, it is advisable to perform a range test to ensure reliable signal reception between the transmitter and your RC helicopter. Choose an open area with a clear line of sight, away from potential sources of interference. Gradually increase the distance between the helicopter and the transmitter while continuously checking for any loss of signal or degradation in control. If any issues arise during the range test, investigate and resolve them before flying.

Storage and Transport

Remove Battery

When storing or transporting your RC helicopter, it is essential to remove the battery. Removing the battery helps prevent unintentional activation and potential damage to the helicopter or surrounding objects. Additionally, storing the battery separately in a cool, dry place, away from direct sunlight or extreme temperatures, helps maintain its performance and prolong its lifespan.

Secure and Protect Blades

Securing and protecting the rotor blades is crucial to prevent damage during storage or transport. Use blade covers or protective sleeves specifically designed for RC helicopter blades. These covers provide a layer of cushioning and prevent the blades from coming into contact with other objects, which can cause bending or chipping. Secure the blade covers in place to ensure they do not come loose during storage or transport.

Use Appropriate Carrying Case

Investing in an appropriate carrying case for your RC helicopter is highly recommended to ensure its safety and protection. Look for a case that is specifically designed for your model or one that provides adequate space, cushioning, and compartments for storing the helicopter, transmitter, batteries, and other accessories. A good carrying case helps keep all components organized and protected from dust, moisture, and impacts.

Avoid Extreme Temperatures

Extreme temperatures can have a significant impact on the performance and lifespan of your RC helicopter. Avoid storing or exposing your helicopter to extreme heat or cold, as this can damage the battery, electronics, and other components. Store your helicopter in a temperature-controlled environment, ensuring it is not exposed to direct sunlight or extreme temperature fluctuations.

Store in Dry and Dust-Free Area

Storing your RC helicopter in a dry and dust-free area is essential to prevent damage to its sensitive electronic components and other parts. Avoid storing the helicopter in humid or damp areas, as moisture can cause corrosion and other issues. Opt for a clean and enclosed storage space, such as a dedicated shelf or cabinet, to protect your helicopter from dust and debris.

Regular Maintenance Schedule

Create Maintenance Calendar

Establishing a maintenance calendar for your RC helicopter helps ensure that all necessary inspections, cleanings, and maintenance tasks are performed regularly. Create a schedule that suits your flying frequency and the manufacturer’s recommendations. Include routine inspections, cleaning sessions, lubrication tasks, and firmware updates. Keeping a maintenance calendar helps you stay organized and proactive in taking care of your RC helicopter.

Set Routine Inspections

Routine inspections are crucial for identifying any potential issues or wear and tear on your RC helicopter. Set a regular interval for conducting comprehensive inspections of the body, battery, blades, landing gear, transmitter, motor, electronics, flight control system, safety features, and other critical components. This allows you to address any issues early on and maintain the optimal performance and safety of your helicopter.

Follow Manufacturer Guidelines

Manufacturers provide specific guidelines for the maintenance and care of their RC helicopter models. It is important to read and follow these guidelines to ensure that you are correctly maintaining your helicopter. Manufacturers often have detailed instructions for routine inspections, cleaning methods, lubrication procedures, firmware updates, and other maintenance tasks. Following these guidelines helps maximize the lifespan and performance of your RC helicopter.

Regularly Update Firmware

Firmware updates can bring significant improvements to the performance, flight characteristics, and functionality of your RC helicopter. Check for firmware updates from the manufacturer periodically and make it a part of your regular maintenance routine. Keep your flight control system, electronics, and other firmware-updatable components up to date to benefit from the latest advancements and optimizations.

Keep Records of Maintenance

Maintaining a detailed record of all the maintenance and servicing performed on your RC helicopter is highly recommended. Record the dates of inspections, cleanings, lubrications, firmware updates, and any repairs or modifications. Note any issues or observations you encounter during flights. Having a comprehensive maintenance log helps you track the history of your RC helicopter and provides valuable information for troubleshooting or warranty claims.

Troubleshooting Tips

Identify Common Issues

Being familiar with common issues that RC helicopter owners encounter can help you troubleshoot and resolve problems more effectively. Research and educate yourself on common issues such as signal interference, motor overheating, erratic flight behavior, or unresponsive controls. By having a good understanding of these common issues, you can quickly identify the underlying cause and apply the appropriate troubleshooting steps.

Refer to User Manual

The user manual provided by the manufacturer is an invaluable resource when troubleshooting issues with your RC helicopter. It contains detailed information on the helicopter’s specifications, setup, operation, and troubleshooting procedures. Always refer to the user manual as your primary source of information when encountering issues. The manual often provides step-by-step instructions for resolving common problems and can save you time and frustration.

Check Online Forums and Communities

Online forums and communities dedicated to RC helicopter enthusiasts can be a great source of troubleshooting tips and solutions. These platforms allow hobbyists to share their experiences, ask questions, and seek advice from more experienced users. Search for forums or communities related to your specific RC helicopter model or brand and engage with the members. Often, you will find helpful insights and recommendations to resolve your specific issue.

Consult RC Helicopter Experts

If you are unable to resolve an issue on your own or through online resources, it may be beneficial to seek assistance from RC helicopter experts. These experts have extensive knowledge and experience in troubleshooting and repairing RC helicopters. Contact local hobby shops, RC clubs, or professional repair services that specialize in RC helicopters. Their expertise and guidance can help you diagnose and fix complex problems that you may encounter.

Perform Basic Repairs if Possible

For minor repairs or adjustments on your RC helicopter, it is worth considering taking the DIY approach if you have the necessary skills and tools. Basic repairs like replacing damaged parts, adjusting linkages, or tightening screws can often be done at home with the proper guidance. Always refer to the user manual or consult online resources before attempting any repairs. However, if you are unsure or uncomfortable with performing repairs, it is advisable to seek professional assistance to prevent further damage or safety risks.

By following this comprehensive RC helicopter maintenance checklist, you can ensure that your helicopter remains in optimal condition for safe and enjoyable flights. Regular inspections, cleanings, lubrication, and battery maintenance are essential for maintaining the longevity and performance of your RC helicopter. Additionally, staying updated with firmware, following manufacturer guidelines, and keeping a record of your maintenance activities are key to ensuring the continuous reliability and safety of your RC helicopter. Remember to consult online resources, seek expert advice when necessary, and perform basic repairs confidently. With proper care and maintenance, your RC helicopter will continue to provide you with hours of exhilarating flying experiences.