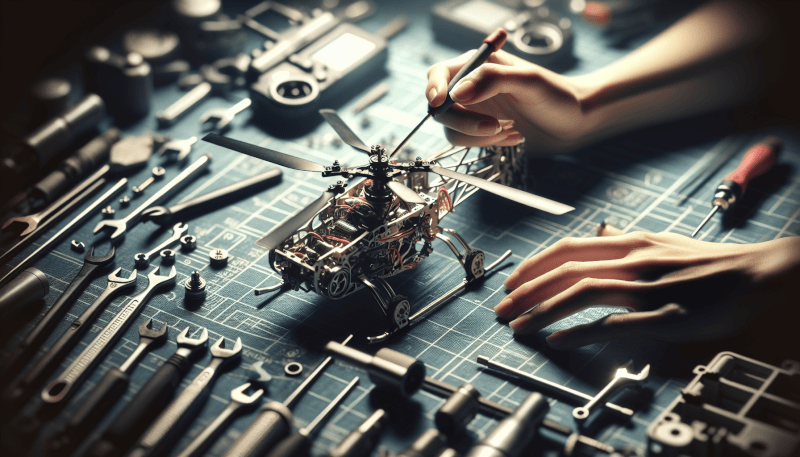

In this article, you will discover the essential steps to successfully perform basic repairs on your RC heli. Whether you are a seasoned RC flyer or just starting out, knowing how to fix common issues can save you time and money. From replacing broken blades to fixing a loose connection, we will guide you through the process with clear instructions and helpful tips. So, grab your toolkit and get ready to become your own RC heli mechanic!

Checking for damage

Inspecting the body

Before performing any repairs on your RC heli, it’s essential to thoroughly inspect the body for any damage. Carefully examine the body frame for cracks or breaks, as these can significantly compromise the stability and performance of your helicopter. Look for any loose or missing screws that may need to be replaced. Additionally, check the canopy for any signs of damage, such as cracks or dents, and ensure it securely attaches to the body.

Examining the rotor blades

The rotor blades are crucial components of your RC heli that require regular inspection. Look for any signs of damage, such as bends, chips, or cracks. If you notice any of these issues, it’s important to replace the damaged blade to maintain safe and stable flight. Ensure that the rotor blades are properly balanced, as unbalanced blades can cause vibrations that affect the overall performance of your helicopter.

Checking the landing gear

The landing gear of your RC heli is responsible for providing stability during takeoff and landing. Inspect the landing skids for any cracks, breaks, or excessive wear. If you identify any damage, it’s necessary to repair or replace the landing gear to prevent accidents during flight. Make sure that the landing skids are securely attached to the helicopter body, as loose or unstable landing gear can impact the handling and control of your heli.

Gathering necessary tools

Screwdriver set

A screwdriver set is an essential tool when performing repairs on your RC heli. Make sure to have a variety of screwdrivers, including both Phillips and flathead, to accommodate different screw types. These handy tools will assist in removing and attaching screws when replacing damaged parts or adjusting components.

Pliers

Pliers come in handy when performing various repair tasks. They can be used to grip and twist wires, hold small parts, or even remove stubborn screws. Invest in a good-quality pair of pliers with a comfortable grip to ensure ease of use during repairs.

Wire cutters

Wire cutters are necessary when repairing or reconnecting wires in your RC heli. They enable you to cut wires to the desired length and remove damaged sections. Having wire cutters with sharp blades is essential for clean and precise cutting, minimizing the risk of wire fraying or damage.

Tape

Tape, such as electrical or adhesive tape, is a versatile tool for repairing your RC helicopter. It can be used to secure loose or disconnected wires, temporarily hold parts in place, or provide added protection to vulnerable areas of the heli. Keep a roll of tape handy in your repair kit to handle various repair situations.

Replacing a damaged rotor blade

Removing the damaged blade

To replace a damaged rotor blade, start by carefully inspecting the blade attachment point on the rotor head. Locate the screws or bolts securing the blade in place. Using an appropriate screwdriver, carefully remove the screws or bolts while ensuring the blade doesn’t fall off.

Attaching the new blade

Once the damaged blade is removed, take your new rotor blade and align it with the attachment point on the rotor head. Insert the screws or bolts through the holes in the blade and into the designated slots on the rotor head. Use your screwdriver to tighten the screws or bolts securely, ensuring proper attachment of the new blade.

Ensuring proper balance

After attaching the new rotor blade, it’s crucial to ensure proper balance to prevent vibrations during flight. Use a balance tool specifically designed for RC helicopter rotor blades to check the balance of each blade. If the blades are imbalanced, make necessary adjustments by adding small pieces of tape to the lighter side until they are evenly balanced.

Repairing a broken landing gear

Removing the broken gear

To repair a broken landing gear, start by identifying the attachment points where the gear connects to the helicopter body. Use a screwdriver to remove any screws or bolts securing the landing gear in place. Once the attachments are removed, gently slide or lift out the broken landing gear from its position.

Installing a new landing skid

With the broken gear removed, take your new landing skid and align it with the attachment points on the helicopter body. Make sure the new landing skid is compatible with your RC heli model. Insert the screws or bolts through the designated holes in the landing skid and secure them tightly with a screwdriver.

Securing the skid in place

To ensure the landing skid remains securely in place, double-check that all screws or bolts are tightened properly. A loose landing skid may affect the stability and handling of your RC heli, so it’s crucial to verify its secure attachment. Once the landing skid is securely installed, visually inspect the repair to ensure everything looks aligned and in proper working condition.

Fixing loose or disconnected wires

Identifying loose or disconnected wires

If your RC heli is experiencing power or control issues, loose or disconnected wires may be the culprit. Inspect the electronic components of your helicopter, such as the receiver, ESC, or motor connections, for any wires that are not securely connected. Look for obvious signs of frayed or damaged wires as well.

Reconnecting wires

Carefully reconnect any loose or disconnected wires in your RC heli. Match the corresponding wire ends and ensure they fit securely into their respective connectors. Use your pliers, if necessary, to twist and tighten the wire connections for a more secure fit. Double-check that all connections are properly tightened to avoid any electrical or power issues.

Using tape to secure connections

After reconnecting the wires, use tape to secure the connections and provide added stability. Wrap a small piece of electrical tape around each reconnected wire to hold them in place firmly. This will minimize the risk of accidental disconnection during flight and ensure a more reliable electrical connection.

Replacing a damaged motor

Removing the old motor

To replace a damaged motor, first, locate the motor attachment points in your RC heli. Disconnect any wires connecting the motor to the ESC or any other electrical components. Carefully unscrew or unclip the old motor from its mounting location. Take note of the wiring connections for the installation of the new motor.

Installing the new motor

With the old motor removed, align the new motor with the mounting location, ensuring that it fits snugly into place. Refer to the documentation or instructions provided with the new motor for proper wiring connections. Once the motor is correctly aligned and wired, secure it in place using screws or clips compatible with your RC heli’s motor mount.

Calibrating the motor

After installing the new motor, it’s crucial to calibrate it to ensure optimal performance. Follow the manufacturer’s instructions to calibrate the motor’s electronic speed controller (ESC) with your RC heli’s remote control. This calibration process may involve specific button combinations or manual throttle adjustments. Proper calibration will allow the motor to work seamlessly with the ESC and provide smooth and controlled flight.

Repairing a damaged antenna

Identifying a damaged antenna

If you notice reduced range or poor signal reception with your RC heli, a damaged antenna could be the cause. Inspect the antenna carefully for any signs of physical damage, such as bends, breaks, or loose connections. Pay close attention to the antenna’s wire and connectors, as these are vulnerable areas.

Replacing the antenna

To replace a damaged antenna, start by identifying the connection point on your RC heli’s receiver or transmitter. Disconnect the old antenna by gently removing it from the designated port. Attach the new antenna to the same port, ensuring a secure and stable connection. The new antenna should be similar in length and design to the original antenna.

Testing the new antenna

After replacing the damaged antenna, it’s important to test the signal strength and range of your RC heli. Power on your helicopter and perform a test flight, carefully monitoring the remote control’s signal reception. If the new antenna improves signal strength and range, you have successfully repaired the antenna. However, if the issues persist, further troubleshooting may be required.

Fixing a malfunctioning remote control

Checking the batteries

If your RC heli is not responding to the remote control’s commands, the batteries may be the culprit. Start by checking the battery compartment of your remote control and ensuring that the batteries are properly inserted. If necessary, replace the batteries with fresh ones to ensure an optimal power supply.

Resetting the remote control

If replacing the batteries does not resolve the issue, try resetting your remote control. Look for a reset button or switch on the remote control and follow the manufacturer’s instructions to perform a reset. This process usually involves holding down the reset button for a specified period of time or cycling the power on and off.

Repairing or replacing buttons

If specific buttons on your remote control are not functioning correctly, they may need to be repaired or replaced. Depending on the design of your remote control, you may be able to disassemble it to access the button mechanisms. Clean any debris or dust that may be causing the buttons to stick or malfunction. If the buttons are damaged beyond repair, consult the manufacturer or an authorized service center for replacement options.

Repairing a faulty ESC

Identifying ESC issues

If you are experiencing erratic motor behavior or power fluctuations, the electronic speed controller (ESC) may be faulty. Inspect the ESC for any signs of physical damage, such as melted components or loose connections. Check all wiring connections to ensure they are secure and properly soldered.

Replacing the ESC

To replace a faulty ESC, start by disconnecting all wires connected to the old ESC. Carefully unscrew or unclip the old ESC from its mounting location. Take note of the wiring connections for the installation of the new ESC. Align the new ESC with the mounting location and secure it in place using screws or clips compatible with your RC heli’s ESC mount. Follow the manufacturer’s instructions for proper wiring connections.

Testing the new ESC

After replacing the faulty ESC, power on your RC heli and perform a test flight to ensure the new ESC is functioning correctly. Monitor motor behavior and power fluctuations during the test flight. If the new ESC resolves the issues, you have successfully repaired the faulty ESC. However, if the problems persist, additional troubleshooting or professional assistance may be necessary.

Troubleshooting a non-responsive motor

Checking the connections

When a motor is not responsive, the first step is to check all connections. Inspect the wiring connections between the motor and the electronic speed controller (ESC). Ensure that the wires are properly connected and there are no loose or disconnected wires. If any issues are found, reconnect and secure the wires as necessary.

Inspecting the motor

If the connections are secure, inspect the motor for any visible signs of damage or malfunction. Look for melted components, loose wiring, or excessive dirt and debris around the motor. Clean the motor if needed, removing any dirt or debris that may be affecting its performance.

Replacing the electronic speed controller (ESC)

If the motor remains non-responsive after checking the connections and inspecting the motor, the issue may lie with the electronic speed controller (ESC). Consider replacing the ESC with a new one that is compatible with your RC heli. Follow the manufacturer’s instructions for proper installation and wiring connections.

In conclusion, performing basic repairs on your RC heli can help maintain its performance and prolong its lifespan. By checking for damage, gathering the necessary tools, and following step-by-step instructions for each repair, you can ensure that your RC heli stays in excellent working condition. Remember to always prioritize safety and consult the manufacturer or professionals if you encounter any challenges or issues beyond your expertise. Happy flying and happy repairing!