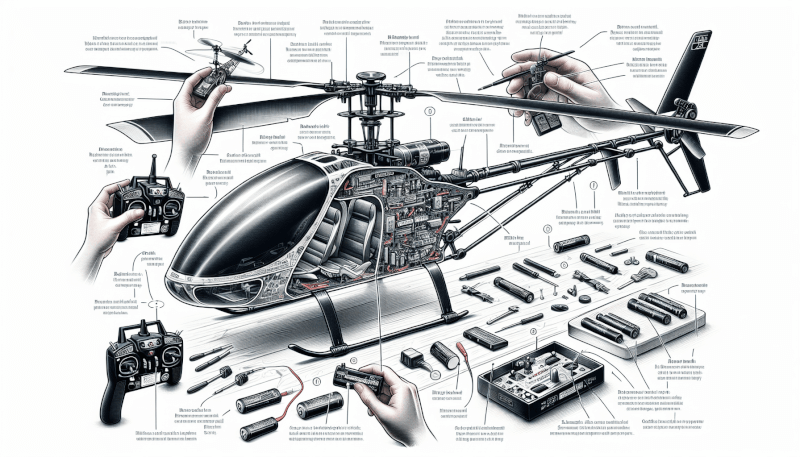

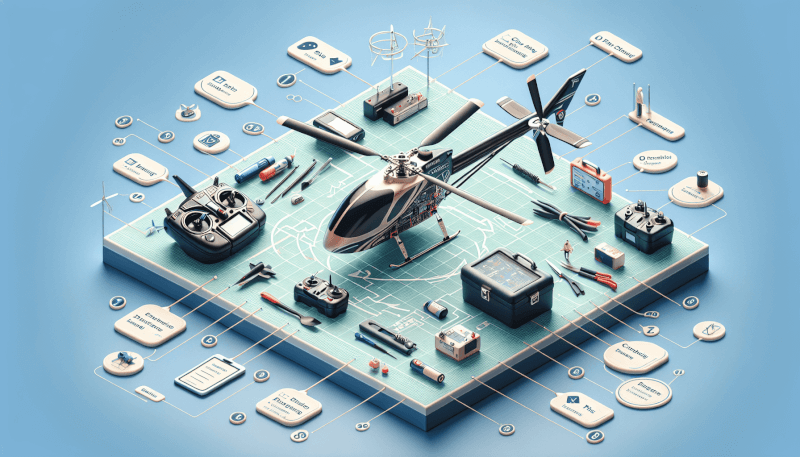

So, you’ve just purchased your brand new RC helicopter and you can’t wait to take it for a spin. But before you do, it’s important to perform a pre-flight check to ensure everything is in perfect working order. In this article, we will guide you through the essential steps to guarantee a safe and successful flight. From inspecting the battery to checking the rotor blades, you’ll be equipped with the knowledge to thoroughly assess your RC heli before takeoff. Let’s get started and make sure your flying experience is nothing short of fantastic!

1. Battery Check

Before every flight, it is essential to inspect your RC heli’s battery to ensure it is in optimal condition. Start by visually inspecting the battery for any signs of physical damage, such as cracks or swelling. If you notice any damage, it is crucial to replace the battery before attempting to fly your heli.

Next, check the battery voltage using a reliable voltage checker or a digital multimeter. Make sure the voltage is within the manufacturer’s recommended range. Flying your heli with a low-voltage battery can lead to poor performance and potentially cause the battery to fail mid-flight.

Lastly, ensure a secure connection between the battery and the heli’s power system. Double-check that the battery connector is properly plugged into the ESC (Electronic Speed Controller) and that there is no excessive movement or looseness.

2. Transmitter Check

The transmitter is your link to the RC heli, so it is crucial to perform a thorough check before taking off. Start by checking the transmitter batteries. Ensure they are fully charged and replace them if necessary. It is always a good idea to carry spare batteries with you to avoid any unexpected interruptions during your flight.

Next, calibrate the controls on your transmitter. This step involves checking the endpoints and adjusting them if needed to achieve the desired control range. Refer to your transmitter’s manual for specific instructions on how to calibrate the controls.

Lastly, confirm that the transmitter has a proper range to communicate with the heli. Make sure you are in an open area, free from any interference, and test the controls at different distances to ensure they respond accurately.

3. Receiver Check

The receiver plays a crucial role in receiving signals from the transmitter and transmitting them to the various components of your RC heli. It is vital to inspect the receiver antenna for any physical damage, such as cuts or fraying. If you notice any damage, replace the antenna to ensure reliable signal reception.

Next, check the connection between the receiver and the heli’s other components, such as the flight controller and servos. Ensure that all the connections are secure and free from any loose or disconnected wires.

Lastly, ensure proper binding between the transmitter and the receiver. Binding allows the transmitter and receiver to establish a secure connection and ensures that the heli responds accurately to your control inputs. Refer to your heli’s manual for instructions on how to bind the transmitter and receiver if needed.

4. Servo Check

Servos are responsible for controlling the various moving parts of your RC heli. It is important to inspect the servo arms for any signs of damage, such as cracks or bending. Damaged servo arms can lead to poor control responsiveness and potentially jeopardize the safety of your flight.

Next, check the servo response by moving the transmitter controls and observing how the servos react. They should move smoothly and without any delays. If you notice any issues, such as jerky movements or inconsistent response, it may indicate a problem with the servo or its connection.

Lastly, ensure that the servos are properly centered. This means that when the controls are in the neutral position, the servo arms should be aligned straight and not tilted to one side. Improper servo centering can affect the stability and control of your RC heli.

5. Flight Control System Check

The flight control system is responsible for stabilizing and controlling your RC heli during flight. It is essential to perform a thorough check to ensure everything is functioning properly.

Start by testing the various flight modes available on your heli. Switch between different modes, such as stability mode and acrobatic mode, and ensure that the heli responds accordingly. Pay attention to any abnormal behavior or unexpected movements, as it may indicate a problem with the flight control system.

Next, check the gyro settings. The gyro helps stabilize the heli by automatically adjusting the rotor speed to counteract any unwanted movements. Make sure the gyro is properly configured and calibrated according to the manufacturer’s instructions.

Lastly, ensure proper control responsiveness by moving the transmitter controls and observing how the heli reacts. The controls should be smooth and precise, with no delays or unresponsive behavior. If you notice any issues, such as sluggish or erratic controls, it may indicate a problem with the flight control system that needs to be addressed before flying.

6. Motor Check

The motor is the powerhouse of your RC heli, providing the necessary thrust for flight. It is crucial to inspect the motor before each flight to ensure it is in optimal condition.

Start by visually inspecting the motor for any signs of physical damage, such as dents or scratches. If you notice any damage, it is essential to replace the motor to avoid potential issues during flight.

Next, check the motor connection to the ESC. Ensure that the connectors are securely plugged in and that there are no loose or disconnected wires. A loose motor connection can lead to poor performance or even motor failure.

Lastly, ensure that the motor rotates in the correct direction. Refer to your heli’s manual to determine the correct rotation direction and verify that the motor spins accordingly. Incorrect motor rotation can affect the stability and control of your RC heli.

7. Rotor Check

The rotor system is responsible for generating lift and controlling the movement of your RC heli. It is crucial to inspect the rotor components before each flight to ensure their integrity.

Start by inspecting the main rotor blades for any signs of damage, such as chips or cracks. Damaged rotor blades can affect the heli’s lift and stability, posing a significant safety risk during flight. If you notice any damage, replace the blades before attempting to fly.

Next, check the rotor head assembly for any loose or worn-out components. Ensure that all the bolts and screws are tight and secure. Loose rotor head assembly can lead to instability and compromised control of your RC heli.

Lastly, ensure proper balance of the rotor blades. Imbalanced blades can cause vibrations, affecting the overall stability and control of your heli. Use a balancer to check the balance of each blade and make any necessary adjustments.

8. Gear Check

The gears in your RC heli play a crucial role in transferring power from the motor to the rotor system. It is important to inspect them regularly to ensure their proper functioning.

Start by inspecting the main and tail gears for any signs of wear or damage. Check for any chipped or missing teeth, as well as any excessive play or looseness. Damaged or worn-out gears should be replaced to avoid potential issues during flight.

Next, check the gear meshing. This refers to the contact between the main and tail gears. The gears should mesh smoothly without any binding or excessive noise. Adjust the gear mesh if necessary to ensure proper engagement and minimize wear.

Lastly, ensure proper lubrication of the gears. Apply the appropriate lubricant to the main and tail gears to minimize friction and maximize their lifespan. Refer to your heli’s manual for the recommended lubrication procedure and interval.

9. Electronic Speed Controller Check

The Electronic Speed Controller (ESC) regulates the power supply to the motor, controlling its speed and performance. It is essential to inspect the ESC before each flight to ensure it is in optimal condition.

Start by inspecting the ESC for any signs of physical damage, such as burns or melted components. If you notice any damage, it is crucial to replace the ESC to avoid potential electrical issues during flight.

Next, check the connection between the ESC and the motor. Ensure that the connectors are securely plugged in and that there are no loose or disconnected wires. A loose ESC connection can lead to poor motor performance or even failure.

Lastly, ensure that the ESC is properly programmed. Verify that the ESC settings, such as battery voltage cutoff and timing, are correctly configured according to the manufacturer’s instructions. Incorrect ESC programming can affect the motor performance and potentially damage the ESC or motor.

10. Overall Inspection and Testing

Once you have completed all the individual checks, it is important to perform a comprehensive inspection of your RC heli before taking off.

Start by inspecting the overall condition of your heli. Check for any loose or missing screws, damaged components, or signs of wear and tear. Replace or repair any damaged parts before flying to ensure the safety and proper functioning of your heli.

Next, perform a pre-flight test hover. This involves lifting your heli a few feet off the ground to check its stability and control responsiveness. Observe how the heli hovers and responds to your control inputs. Pay attention to any abnormal behavior or unexpected movements and address any issues before proceeding with a full flight.

Lastly, double-check all the controls and systems of your heli. Move the transmitter controls and verify that the heli responds accurately and smoothly. Ensure that all the components, such as the battery, transmitter, receiver, servos, flight control system, motor, rotor, gears, and ESC, are functioning properly and ready for flight.

By diligently performing a pre-flight check on your RC heli, you can ensure its safe operation and enhance your overall flying experience. Remember to follow the manufacturer’s instructions and guidelines for your specific heli model, as different helis may have unique requirements. Happy flying!