So, you’ve just experienced a little mishap with your beloved RC heli. Don’t worry, it happens to the best of us! But what comes next? Before you can take to the skies again, it’s crucial to perform a thorough post-crash inspection. This article will guide you through the process, ensuring that you don’t miss any potential damage or necessary repairs. By following these simple steps, you’ll be back at the controls of your RC heli in no time, soaring through the sky with confidence and peace of mind.

Preparation

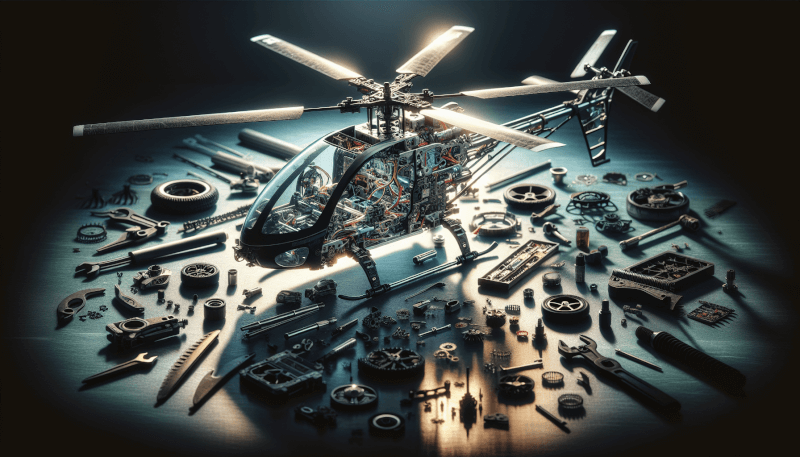

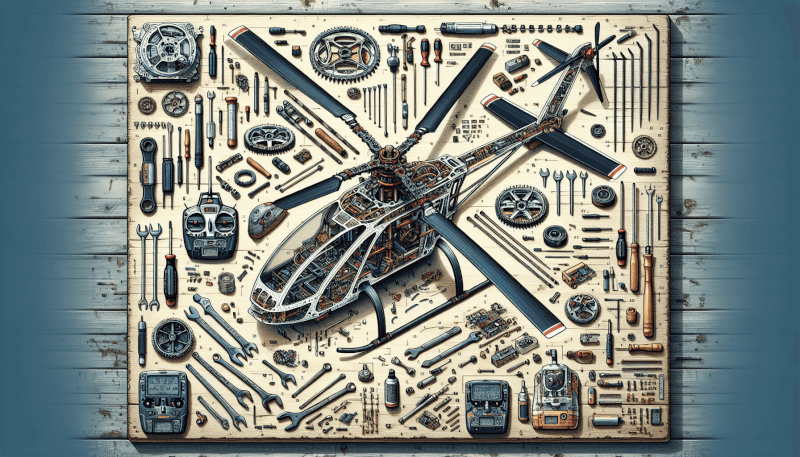

Before beginning your post-crash inspection, it’s important to gather all the necessary tools and supplies. You’ll need a set of screwdrivers, pliers, and a small adjustable wrench at the very least. Additionally, it’s crucial to ensure that you have a clean and well-lit workspace. This will allow you to thoroughly examine your RC heli and make accurate assessments of its condition.

Visual Inspection

The first step in the post-crash inspection process is to visually assess the overall condition of your RC heli. Take a close look at the entire aircraft and check for any visible damage or deformities. Look out for any cracks, dents, or other signs of impact. It’s important to inspect the blades carefully, as they are often the most susceptible to damage. Look for any cracks or chips that may compromise the structural integrity of the blades.

Mechanical Inspection

Next, it’s time to examine the mechanical components of your RC heli. Start by checking the rotor head for any signs of damage. Look for any bent or broken parts that may need to be replaced. Evaluate the tail rotor assembly as well, ensuring that it is securely attached and functioning properly. Additionally, inspect the main gear and motor shaft for any signs of wear or damage. These components are crucial for the proper functioning of your RC heli, so it’s essential to thoroughly inspect them.

Electronics Inspection

Moving on to the electronics, inspect the wires and connectors for any damage. Look for frayed or loose wires, as well as any connectors that may be broken or corroded. Pay close attention to the battery and its connections, as these are vital for powering your RC heli. Check for any signs of damage or leakage. Additionally, evaluate the receiver and servo connections to ensure they are secure and functioning correctly. Any issues with the electronics can severely impact the performance of your RC heli, so it’s important to address any problems promptly.

Flight Control Inspection

The flight control system is responsible for maneuvering your RC heli, so it’s crucial to thoroughly inspect it. Check the control linkages for any signs of wear or damage. Look for loose or broken parts that may need to be replaced. It’s also important to ensure that the control surfaces move smoothly and precisely. Check that there is no binding or resistance when you move the controls. If you notice any issues, such as excessive play or stiffness, it’s important to address them before attempting to fly your RC heli again.

Transmission Inspection

The transmission system of your RC heli is responsible for transferring power from the motor to the rotor blades. Therefore, it’s important to inspect it for any potential issues. Start by examining the transmission belt or gear system, depending on the type of RC heli you have. Look for any signs of wear, damage, or misalignment. Additionally, check for any slipping in the transmission system, as this can severely impact the performance and stability of your RC heli.

Fuel System Inspection

If your RC heli runs on fuel, it’s important to thoroughly inspect the fuel system. Evaluate the fuel tank and the lines for any leaks or damage. Look for cracks or loose connections that may cause fuel leakage. It’s also crucial to ensure proper fuel flow and cleanliness of the fuel filter. Any issues with the fuel system can lead to engine failure or poor performance, so it’s essential to address them before flying your RC heli again.

Radio Transmitter Inspection

The radio transmitter is the control center of your RC heli, so it’s important to inspect it thoroughly. Start by checking the battery level and condition. Ensure that the battery is fully charged and functioning correctly. Inspect the antenna for any signs of damage, such as bends or cuts. A damaged antenna can interfere with the signal transmission and affect the control of your RC heli. If you notice any issues with the battery or antenna, replace them to ensure reliable control during flight.

Testing and Calibration

Once you have completed all the necessary inspections, it’s time to perform a thorough pre-flight check. This includes testing all the control surfaces to ensure they move correctly and smoothly. Check the responsiveness of the controls and make any necessary adjustments. Additionally, it may be necessary to calibrate the gyro and flight controller if you notice any instability or erratic behavior during the pre-flight check. Calibration will help ensure optimal performance and stability during flight.

Repair and Maintenance

If you discovered any damaged components or identified areas that require maintenance during the inspection, it’s important to address those issues promptly. Order replacement parts for any damaged components to ensure the safe and reliable operation of your RC heli. Once the repairs are complete, it’s crucial to clean and lubricate the necessary parts. This will help maintain the longevity of your RC heli and ensure it continues to perform at its best.

Performing a post-crash inspection on your RC heli is an important step in maintaining its performance and ensuring your safety while flying. By following the outlined steps and thoroughly inspecting each aspect of your RC heli, you can identify any issues and address them before they result in further damage or accidents. Remember to always take the time to properly prepare your workspace and use the necessary tools and supplies to ensure a comprehensive inspection. By performing regular inspections and maintenance, you can enjoy the exciting world of RC flying while keeping your RC heli in top-notch condition.