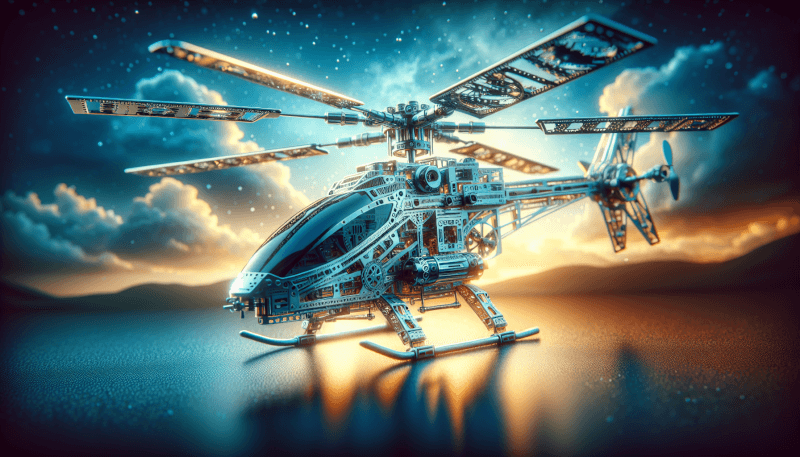

Have you ever dreamed of flying your very own remote-controlled helicopter? Well, now you can turn that dream into a reality by building your own custom RC heli from scratch. In this article, you will discover the step-by-step process of creating your personalized RC heli, from selecting the right components and tools to assembling and fine-tuning your creation. Get ready to embark on an exciting journey through the world of RC helicopters, where you’ll gain the knowledge and skills to bring your imagination to life in the form of a soaring, maneuverable aircraft. Get ready to take to the skies!

Choosing the Right Components

When it comes to building your own custom RC helicopter, it all starts with choosing the right components. This crucial step ensures that your helicopter performs optimally and meets your specific needs.

Researching Different RC Helicopter Models

Before diving into the component selection process, it’s important to research and familiarize yourself with different RC helicopter models. This will give you a better understanding of the features, capabilities, and performance of various models available in the market. Take note of the size, flight characteristics, and level of complexity of different models to help you make an informed decision.

Selecting the Appropriate Frame

The frame is the foundation of your RC helicopter, so selecting the appropriate one is essential. Consider factors such as the size, material, and design of the frame. Aluminum frames are lightweight and durable, while carbon fiber frames offer increased rigidity. Additionally, ensure that the frame is compatible with the size of the components you plan to use.

Choosing the Right Motors and ESCs

The motors and Electronic Speed Controllers (ESCs) are crucial components for the power and control of your RC helicopter. Consider factors such as motor type, KV rating, and ESC current rating. Brushless motors are commonly used for their efficiency and power, while ESCs regulate the motor’s speed. Ensure that the motors and ESCs are compatible with each other and provide sufficient power for your desired flight capabilities.

Selecting the Proper Radio System

The radio system is responsible for transmitting your commands to the RC helicopter, so selecting the proper one is essential for reliable control. Consider factors such as the number of channels, frequency range, and transmitter features. Opt for a radio system that offers enough channels to control all the necessary functions of your custom RC helicopter and has a reliable range.

Picking the Right Battery and Charger

The battery and charger are crucial components for powering your RC helicopter. Consider factors such as the battery voltage and capacity, as well as the charger’s compatibility and charging capabilities. LiPo batteries are commonly used for their high energy density and lightweight characteristics. Ensure that the battery and charger are compatible with each other and provide sufficient power and charging options for your flying requirements.

Building the Frame

Once you have chosen the right components for your custom RC helicopter, it’s time to start building the frame. This section will guide you through the process of assembling the frame and attaching various components.

Assembling the Main Frame

Start by assembling the main frame of your RC helicopter. Follow the instructions provided by the manufacturer and ensure that all the parts are securely attached. It’s essential to double-check the alignment and tightness of screws and bolts to ensure the structural integrity of the frame.

Installing the Landing Skids

Next, install the landing skids onto the main frame. These provide stability and support during takeoff and landing. Follow the manufacturer’s instructions and securely attach the landing skids to the designated mounting points on the frame. Ensure that they are properly aligned and provide a stable base for your RC helicopter.

Attaching the Tail Boom and Tail Fin

The tail boom and tail fin provide stability and control during flight. Attach the tail boom to the rear of the main frame and secure it tightly. Then, attach the tail fin to the tail boom using the provided screws or bolts. Ensure that both the tail boom and tail fin are aligned properly for optimal flight performance.

Mounting the Swashplate Assembly

The swashplate assembly is responsible for translating your control inputs into the desired movements of your RC helicopter. Mount the swashplate assembly onto the main shaft of the frame. Ensure that it moves freely and smoothly without any binding or interference. Double-check the alignment and functionality of the swashplate assembly before proceeding.

Connecting the Tail Rotor

The tail rotor is crucial for maintaining yaw control of your RC helicopter. Connect the tail rotor assembly to the tail boom and ensure that it rotates freely. Double-check the tightness of the screws or bolts to prevent any unwanted movement or vibration during flight. Properly align and balance the tail rotor blades for optimal performance.

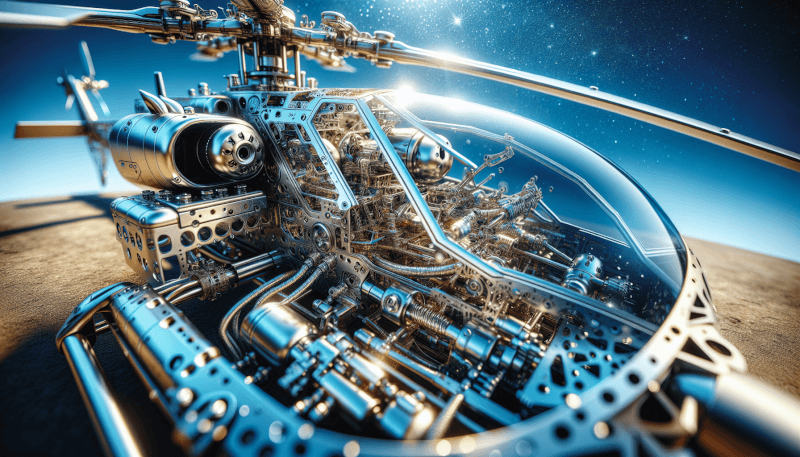

Installing the Electronics

With the frame of your custom RC helicopter built, it’s time to install the electronics. This section will guide you through the process of mounting and connecting the necessary electronic components.

Mounting the Flight Controller

The flight controller is the brain of your RC helicopter, responsible for stabilizing and controlling its flight. Mount the flight controller onto the main frame, ensuring that it is securely attached and protected from vibration. Follow the manufacturer’s instructions for proper orientation and placement of the flight controller.

Connecting the GPS System

If you plan to use GPS capabilities for your RC helicopter, connect the GPS system to the flight controller. Follow the manufacturer’s instructions and ensure that the GPS antenna has a clear view of the sky for optimal signal reception. Properly secure the GPS system to prevent any unwanted movement or interference during flight.

Attaching the Receiver and Antennas

The receiver is responsible for receiving your commands from the radio system. Attach the receiver to the frame of the RC helicopter, ensuring that it is securely mounted and protected from vibration. Connect the antennas to the receiver, following the manufacturer’s instructions for proper placement and orientation. Ensure that the antennas have sufficient clearance and are securely positioned.

Wiring the Motors and ESCs

Properly wiring the motors and ESCs is crucial for the power and control of your RC helicopter. Refer to the wiring diagrams provided by the manufacturer and connect the motors and ESCs according to their designated positions. Take note of the correct polarity and ensure that all connections are secure and free from any loose wires or connectors.

Installing the Battery and Power Distribution Board

With the electronics connected, install the battery and power distribution board. Ensure that the battery is securely fastened to the frame and that the power distribution board is properly mounted. Double-check all connections and ensure that there are no loose wires or exposed contacts. Properly route and secure the wiring to prevent any interference or damage during flight.

Configuring the Radio System

After installing the electronics, it’s time to configure the radio system for optimal control of your RC helicopter. This section will guide you through the process of binding the receiver, programming the radio transmitter, and setting up flight modes and failsafes.

Binding the Receiver and Transmitter

Binding the receiver and transmitter is a crucial step for establishing a reliable connection between the two. Follow the manufacturer’s instructions for the specific radio system you are using. Ensure that both the receiver and transmitter are in the binding mode and that they are within the required range for a successful binding process.

Programming the Radio Transmitter

Once the receiver and transmitter are successfully bound, you can program the radio transmitter according to your preferences. Follow the manufacturer’s instructions for accessing the programming menu and adjusting the necessary settings. Take your time to customize the controls, trims, and dual rates to achieve the desired response and feel of your RC helicopter.

Calibrating the Stick Movements

Proper calibration of the stick movements is essential for accurate control of your RC helicopter. Follow the manufacturer’s instructions for calibrating the stick movements on your radio transmitter. Ensure that the stick movements correspond accurately to the desired control outputs on the flight controller.

Setting up Flight Modes and Failsafes

Flight modes allow you to switch between different flight characteristics and behaviors. Set up flight modes according to your preferences and the capabilities of your flight controller. Additionally, configure failsafes to ensure that your RC helicopter reacts appropriately in case of signal loss or radio interference. Double-check the settings and test the functionality of flight modes and failsafes before proceeding to flight testing.

Testing and Troubleshooting the Radio System

Before taking your custom RC helicopter for its first flight, thoroughly test and troubleshoot the radio system. Ensure that all controls are functioning as intended, and that there are no glitches or interference. Test the range and signal strength of the radio system in different locations to identify and address any potential issues.

Setting up the Flight Controller

The flight controller plays a crucial role in stabilizing and controlling your RC helicopter. This section will guide you through the process of configuring the flight controller software, calibrating the IMU and sensors, setting up flight modes and PID values, and adjusting the exponential and rates.

Configuring the Flight Controller Software

Before proceeding with the configuration process, ensure that you have the latest version of the flight controller software installed. Connect the flight controller to your computer and access the software interface. Follow the software’s instructions to configure basic parameters such as the frame type, motor layout, and sensor orientation.

Calibrating the IMU and Sensors

Calibrating the Inertial Measurement Unit (IMU) and other sensors ensures accurate readings and optimal performance. Follow the software’s instructions for calibrating the IMU and any other sensors present on your flight controller. Proper calibration eliminates any drift or inaccuracies in the sensor data, resulting in better stability and control during flight.

Setting up the Flight Modes and PID Values

Flight modes and PID (Proportional, Integral, Derivative) values dictate the behavior and response of your RC helicopter. Configure the flight modes according to your preferences and desired flight characteristics. Additionally, adjust the PID values to fine-tune the control and stability of the aircraft. It’s recommended to start with default values and gradually make small adjustments based on flight testing.

Adjusting the Exponential and Rates

Exponential and rates settings determine the sensitivity and response of your RC helicopter’s controls. Exponential settings allow you to shape the input-output curves for smoother or more aggressive response. Rates settings determine the maximum movement range and speed of the controls. Customize these settings according to your personal flying style and preferences, ensuring a comfortable and controllable experience.

Verifying the Motor Outputs and Orientation

Verifying the motor outputs and orientation is crucial for proper control and stability of your RC helicopter. Follow the software’s instructions to confirm that each motor is correctly assigned and that the propellers spin in the correct direction. Additionally, verify that the flight controller recognizes the correct motor rotation orientations to ensure that all control inputs result in the desired movements.

Installing and Configuring the Propellers

Choosing and installing the right propellers is vital for the performance and efficiency of your RC helicopter. This section will guide you through selecting the right propellers, balancing them, mounting them on the motors, testing their performance, and fine-tuning their settings.

Selecting the Right Propellers

Selecting the right propellers depends on factors such as the size, weight, and type of your RC helicopter, as well as your desired flight characteristics. Refer to the manufacturer’s guidelines and recommendations for suitable propellers for your specific setup. Take note of the propeller size, pitch, and material to ensure compatibility and optimal performance.

Balancing the Propellers

Balancing the propellers minimizes vibrations and ensures smooth operation. Use a propeller balancing tool or balancer to determine any inconsistencies in weight distribution. Add small weights or remove material from the heavier side of the propeller until it rests perfectly balanced. Repeat the process for all propellers to achieve maximum efficiency and reduce stress on the motors.

Mounting the Propellers on the Motors

After balancing the propellers, mount them on the motors following the manufacturer’s instructions. Ensure that each propeller is securely attached and tightened properly. Double-check the rotation direction of each motor-propeller combination to ensure that they are consistent with the flight controller’s configuration.

Testing the Propeller Performance

Before fine-tuning the propeller settings, conduct tests to evaluate the propeller performance. Observe the response, efficiency, and stability of your RC helicopter during hover and various flight maneuvers. Take note of any vibrations, vibrations, or abnormal behavior that may indicate an imbalance or mismatch between the propellers and the aircraft.

Fine-tuning the Propeller Settings

Based on the test results, fine-tune the propeller settings for optimal performance. Adjust the pitch or size of the propellers if necessary to achieve the desired flight characteristics. Gradually make small adjustments, test the changes, and evaluate their impact on the flight performance. Aim to achieve a balance between stability, responsiveness, and efficiency for the best flying experience.

Mounting the Canopy and Finishing Touches

With the major components installed and configured, it’s time to add the finishing touches to your custom RC helicopter. This section will guide you through mounting the canopy, adding decals and custom paint, securing and protecting the electronics, attaching the tail rotor blades, and performing a final check and inspection.

Installing the Canopy and Canopy Mounts

The canopy not only provides a sleek appearance but also helps protect the internal components from dust, debris, and damage. Mount the canopy onto the frame using the designated canopy mounts or clips. Ensure that the canopy is securely attached and allows access to the necessary components for future maintenance or modifications.

Adding Decals and Custom Paint

Personalize your custom RC helicopter by adding decals or applying custom paint. Use high-quality decals or paint that can withstand the rigors of RC helicopter flight and weather conditions. Be creative and choose designs that reflect your style and preferences. Take your time to apply the decals or paint carefully, ensuring a clean and professional-looking finish.

Securing and Protecting the Electronics

Ensure that all electronic components are properly secured and protected from vibration and potential damage. Use cable ties, adhesive tape, or other suitable means to secure loose wires or connectors. Consider using protective covers or shields to prevent physical damage to sensitive components. Double-check the secureness of all connections and perform a thorough visual inspection of the electronics.

Attaching the Tail Rotor Blades

Attach the tail rotor blades to the tail rotor assembly, ensuring that they are securely mounted and balanced. Align the blades with the tail rotor assembly and tighten the screws or bolts. Verify that the tail rotor blades rotate freely without any binding or interference. Properly balanced and aligned tail rotor blades contribute to stable yaw control during flight.

Final Check and Inspection

Before taking your custom RC helicopter for its maiden flight, perform a final check and inspection of all components and their connections. Ensure that all screws, bolts, and fasteners are tightened properly. Verify that all control surfaces move freely and smoothly, without any binding or interference. Double-check the orientation and alignment of the motor and propeller combinations. Inspect the overall condition and integrity of the RC helicopter, ensuring that there are no visible signs of damage or loose parts.

Testing and Flying Your Custom RC Heli

After successfully building and preparing your custom RC helicopter, it’s time to put it to the test and take it for a flight. This section will guide you through performing a pre-flight check, verifying the motor outputs and direction, testing the gyro and flight stability, adjusting the trim and centering, and taking your first flight.

Performing a Pre-flight Check

Before every flight, it’s essential to perform a thorough pre-flight check to ensure that all systems are functioning properly. Check the battery level, control responsiveness, and overall structural integrity of the RC helicopter. Double-check that all connections and components are securely attached and functioning as intended. Inspect the propellers for any damage or imbalance. Verify that the radio system has a strong signal and connection with the receiver.

Verifying the Motor Outputs and Direction

Verify that the motor outputs and direction are correctly configured and aligned. Slowly increase the throttle and observe the rotation direction of each motor. Ensure that the propellers spin according to the flight controller’s configuration. Take note of any abnormal motor behavior or rotation direction and address any issues before proceeding to flight testing.

Testing the Gyro and Flight Stability

Controlled hovering is a great way to test the gyro and flight stability of your RC helicopter. Gradually increase the throttle and observe how the aircraft responds and stabilizes. Ensure that the flight controller effectively counters any drift or movement and maintains a stable hover. Make small adjustments as necessary to achieve optimal stability and control.

Adjusting the Trim and Centering

Trim and centering adjustments are necessary to achieve neutral control surfaces and flight stability. Observe the control inputs and outputs during flight and make small trim adjustments to eliminate any unwanted drift or bias. Ensure that the control surfaces return to their neutral position without any binding or obstruction.

Taking Your First Flight

Once you have performed all necessary checks and adjustments, and you feel confident in the readiness of your RC helicopter, it’s time to take it for its first flight. Start by performing simple maneuvers such as takeoff, hover, and gentle turns. Gradually increase the complexity and intensity of the flight as you become more comfortable and familiar with your custom RC helicopter. Focus on maintaining smooth and controlled movements, avoiding sudden and erratic inputs. Enjoy the experience and have fun exploring the capabilities of your creation.

Troubleshooting and Maintenance

As with any complex system, it’s important to be familiar with troubleshooting and performing regular maintenance on your custom RC helicopter. This section will guide you through identifying and resolving common issues, performing regular maintenance tasks, replacing faulty components, troubleshooting electrical and mechanical problems, and seeking professional help when needed.

Identifying and Resolving Common Issues

Common issues in RC helicopters include motor or ESC failures, control system malfunctions, and power distribution problems. Solving these issues requires troubleshooting skills and attention to detail. Consult the manufacturer’s documentation and relevant online resources to identify the possible causes and solutions for the specific issue you encounter. Take a systematic approach and address one potential cause at a time to isolate and resolve the problem.

Performing Regular Maintenance

Regular maintenance is essential for keeping your custom RC helicopter in optimal condition and prolonging its lifespan. Schedule regular inspections to check for any loose screws or connectors, signs of wear or damage, and any necessary lubrication or cleaning. Follow the manufacturer’s guidelines for recommended maintenance tasks such as bearing replacements or gear lubrication. This proactive approach will help prevent issues and ensure a reliable and enjoyable flying experience.

Replacing Faulty Components

If you encounter a faulty component during the troubleshooting process, it’s important to replace it with a suitable and compatible replacement. Consult the manufacturer’s documentation and seek professional advice if necessary to ensure that the replacement component meets the required specifications and performance standards. Follow the manufacturer’s instructions for safely removing the faulty component and properly installing the new one.

Troubleshooting Electrical and Mechanical Problems

Electrical and mechanical problems can arise during the building, configuration, or flight phases of your custom RC helicopter. Troubleshooting these problems requires a systematic and logical approach. Utilize troubleshooting guides, forums, and other resources to identify potential causes and solutions for the specific problem you encounter. Test and verify each potential cause to isolate and resolve the issue effectively.

Seeking Professional Help

Building and troubleshooting a custom RC helicopter can be a challenging task, especially for beginners. If you encounter issues or difficulties that you are unable to resolve on your own, do not hesitate to seek professional help. Many RC hobby shops offer expert advice and services for diagnosing and resolving complex problems. Professional assistance can save you time, frustration, and potential damage to your RC helicopter.

Advanced Customizations and Upgrades

Once you have mastered the basics of building and flying your custom RC helicopter, you may consider advanced customizations and upgrades. This section will briefly explore some options for upgrading the motors and ESCs, installing advanced flight controllers, adding optional features and accessories, modifying the canopy for performance, and implementing custom programming and configurations.

Upgrading the Motors and ESCs

Upgrading the motors and ESCs can significantly enhance the performance and capabilities of your RC helicopter. Higher KV rated motors can provide increased power and speed, while more advanced ESCs offer smoother and more precise control. However, it’s crucial to ensure compatibility with the existing components and to make any necessary adjustments to the flight controller and software settings.

Installing Advanced Flight Controllers

Advanced flight controllers offer additional features and functionality for more advanced flying techniques and maneuvers. These may include advanced stabilization algorithms, autonomous flight modes, or advanced telemetry options. However, installing and configuring advanced flight controllers often requires a higher level of technical knowledge and expertise. Ensure that you thoroughly research and understand the capabilities and requirements of the chosen flight controller before attempting the upgrade.

Adding Optional Features and Accessories

Adding optional features and accessories can customize your RC helicopter to suit your specific preferences and flying style. These may include LED lights for night flying, camera mounts for aerial photography or videography, or additional sensors for enhanced control and stability. Ensure that any added features or accessories are securely mounted and properly integrated with the existing components.

Modifying the Canopy for Performance

Modifying the canopy can go beyond aesthetics and actually improve the performance of your RC helicopter. Consider adjusting the shape or adding aerodynamic elements to optimize the airflow and reduce drag. However, it’s important to thoroughly test any modifications and evaluate their impact on the flight characteristics before implementing them permanently.

Implementing Custom Programming and Configurations

Custom programming and configurations offer endless possibilities for tailoring your RC helicopter to your specific needs and preferences. Advanced flight controller software often provides options for customizing control curves, flight modes, and even complex automation tasks. However, it’s essential to have a deep understanding of the software and its capabilities to avoid potential issues or unintended consequences. Always make small adjustments and thoroughly test each modification to ensure optimal performance and safety.

In conclusion, building your own custom RC helicopter from scratch is an exciting and rewarding endeavor. By carefully choosing the right components, assembling the frame, installing the electronics, configuring the radio system and flight controller, and fine-tuning the propellers, you can create a personalized RC helicopter that suits your specific needs and preferences. Remember to perform thorough tests, perform regular maintenance, and troubleshoot any issues that may arise. With proper care and attention, your custom RC helicopter will provide countless hours of enjoyment and excitement in the world of remote-controlled aviation.