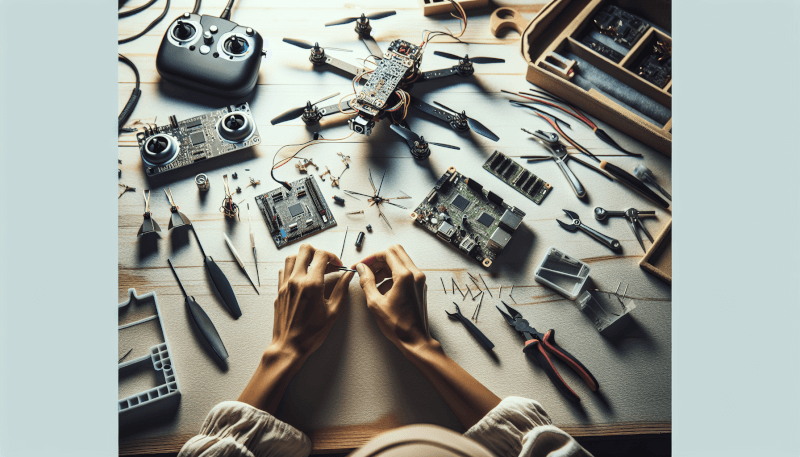

So, you’ve decided to take the plunge and build your own custom drone. Exciting times are ahead! Whether you’re a tech enthusiast or simply love capturing breathtaking aerial shots, building your own drone can be a rewarding experience. Don’t worry if you’re new to this, as this beginner’s guide will walk you through the process step by step. From selecting the right components to understanding the basics of flight control, you’ll be soaring through the sky in no time. So, let’s get ready to assemble your very own custom drone and embark on an incredible journey of exploration and creativity.

Drone Components

Frame

The frame is the foundation of any drone and provides the structure that holds all the other components together. It is crucial to choose the right frame that suits your needs and goals. There are various types of frames available, such as quadcopter, hexacopter, and octocopter. Each type offers different flight characteristics and capabilities. Additionally, frames come in different materials, including carbon fiber, aluminum, and plastic. The choice of material depends on factors like durability, weight, and budget. Lastly, it is essential to consider the size and weight of the frame, as it affects the drone’s maneuverability and payload capacity.

Motors

Motors are responsible for providing the necessary thrust to lift and maneuver the drone. When selecting motors, you need to consider whether to go for brushed or brushless motors. Brushed motors are cheaper but less efficient compared to brushless motors. Brushless motors offer better performance, longer lifespan, and higher power output. Another factor to consider is the Kv rating, which indicates the rotational speed of the motor. Higher Kv ratings result in faster rotation, but it also consumes more power. Lastly, the thrust-to-weight ratio is crucial as it determines how agile and responsive your drone will be.

Electronic Speed Controllers (ESCs)

ESCs are essential components that control the speed and direction of the motors. They convert the signals from the flight controller into appropriate currents to drive the motors. There are various types of ESCs available, including SimonK, BLHeli, and KISS. It is crucial to choose ESCs that are compatible with your chosen motors and flight controller. Additionally, some ESCs require programming for optimal performance, so it’s essential to consider this aspect as well.

Flight Controller

The flight controller is the brain of the drone, responsible for stabilizing and controlling the aircraft’s movements. It processes sensor data, such as the accelerometer, gyroscope, and magnetometer, to maintain stability and control. There are different types of flight controllers available, including those designed specifically for drones like the Naze32, Pixhawk, and Betaflight. When selecting a flight controller, consider the features it offers, such as GPS, autonomous flight modes, and telemetry. Also, ensure compatibility with your chosen frame and ESCs. Pay attention to mounting options and connections, as proper placement and secure connections are vital for optimal performance.

Battery

The battery is a crucial component that provides the power to the motors and other electronics on the drone. When choosing a battery, consider the voltage and capacity. The voltage determines the overall power output, while the capacity affects the flight time. It is essential to find a balance between the two based on your requirements. Additionally, consider the physical size and weight of the battery, as it affects the drone’s weight distribution and flight characteristics. Lastly, prioritize battery safety by choosing reputable brands and following proper charging and usage guidelines.

Propellers

Propellers are responsible for creating the necessary thrust to lift the drone off the ground and propel it forward. When selecting propellers, consider the size and pitch. The size affects the lifting capacity and maneuverability, while the pitch determines the thrust generated. It is crucial to choose propellers that are compatible with your chosen motors and frame. Additionally, consider the material used in the construction of the propellers. Common materials include plastic, carbon fiber, and wood. Each material has its advantages and disadvantages, so choose based on factors like durability, weight, and cost. Lastly, ensure the balance and correct rotation of the propellers for smooth and stable flight.

Tools Needed

To assemble your own custom drone, you will need the following tools:

Screwdriver set

A screwdriver set with various sizes and types of screwdrivers is essential for assembling and disassembling components.

Side cutters

Side cutters are useful for cutting wires and zip ties during the assembly process. They provide a clean and precise cut.

Heat shrink tubing

Heat shrink tubing is used to insulate and protect soldered connections. It shrinks when heated, providing a tight and secure covering.

Soldering iron and solder

A soldering iron and solder are necessary for connecting wires, ESCs, and other components that require electrical connections.

Electrical tape

Electrical tape is used for securing and insulating wires and connections. It provides a simple and effective method for preventing shorts and ensuring electrical safety.

Having these tools on hand will make the assembly process smoother and more efficient. They are readily available at hardware stores and online retailers. It is essential to invest in good quality tools to ensure durability and reliability.

Choosing the Right Frame

When it comes to choosing the right frame for your custom drone, there are several factors to consider.

Types of frames

There are various types of frames available, each offering different flight characteristics and capabilities. The most common types are quadcopter, hexacopter, and octocopter. Quadcopters are the most popular choice for beginners due to their simplicity and stability. Hexacopters and octocopters offer increased redundancy and payload capacity but are more complex to build and operate.

Materials

Frames are made from different materials, including carbon fiber, aluminum, and plastic. Carbon fiber frames are lightweight and durable but tend to be more expensive. Aluminum frames are sturdy but add weight to the drone. Plastic frames are affordable but may lack durability. Consider your budget and requirements when selecting a frame material.

Size and Weight considerations

The size and weight of the frame have a significant impact on the drone’s maneuverability and payload capacity. Smaller frames are more agile and can navigate tight spaces, while larger frames can carry heavier payloads. Balance the size and weight based on your flying goals and the specific tasks you intend to perform with your drone.

By considering the types of frames, materials, and size and weight considerations, you can choose a frame that meets your needs and goals for your custom drone.

Selecting Motors

Choosing the right motors for your custom drone is crucial for performance and efficiency.

Brushed or Brushless motors

The choice between brushed and brushless motors depends on your budget and requirements. Brushless motors are generally more efficient, have a longer lifespan, and offer higher power output. Brushed motors, on the other hand, are more affordable but may require more maintenance and have lower performance.

Kv rating

The Kv rating of a motor indicates its rotational speed in revolutions per minute (RPM) per volt. Higher Kv ratings result in faster rotation but also consume more power. Consider the desired speed and power requirements of your drone when selecting the Kv rating.

Thrust-to-Weight Ratio

The thrust-to-weight ratio is a critical factor in determining the agility and responsiveness of your drone. It is the ratio of the thrust generated by the motors to the weight of the drone. Aim for a high thrust-to-weight ratio for better maneuverability and acrobatic performance.

By considering brushed or brushless motors, Kv rating, and thrust-to-weight ratio, you can select motors that provide the desired performance and efficiency for your custom drone.

Understanding Electronic Speed Controllers (ESCs)

Electronic Speed Controllers (ESCs) play a crucial role in controlling the speed and direction of the motors. Here’s what you need to know.

Role of ESCs

ESCs convert the signals from the flight controller into appropriate currents to drive the motors. They regulate the speed and direction of the motors, allowing the drone to maintain stability and respond to pilot inputs.

Types of ESCs

There are various types of ESCs available, including SimonK, BLHeli, and KISS. Each type offers different features and performance characteristics. Research and choose ESCs that are compatible with your chosen motors and flight controller.

Compatibility with Motors

It is crucial to ensure that the ESCs you choose are compatible with your selected motors. Consider the voltage and amperage ratings of both the ESCs and motors to ensure proper functionality and prevent damage.

Programming ESCs

Some ESCs require programming for optimal performance. Programming allows you to adjust parameters such as motor timing, throttle response, and motor brake settings. If you choose ESCs that require programming, be sure to follow the manufacturer’s instructions and recommendations.

By understanding the role of ESCs, different types available, compatibility with motors, and the possibility of programming, you can select and configure ESCs that suit your custom drone’s needs.

Flight Controller Options

The flight controller is the brain of your drone, responsible for stabilizing and controlling its movements. Consider the following when selecting a flight controller.

Types of Flight Controllers

There are various types of flight controllers available, each offering different features and capabilities. Some popular options include Naze32, Pixhawk, and Betaflight. Research and choose a flight controller that aligns with your goals and requirements.

Features to consider

Consider the features offered by the flight controller, such as GPS, autonomous flight modes, and telemetry. These features can enhance your drone’s capabilities and allow for advanced flight capabilities. Take note of the specific features that are important to you and ensure compatibility with your chosen frame and other components.

Mounting and connections

Proper mounting and secure connections of the flight controller are crucial for optimal performance. Different flight controllers may have specific mounting requirements and connection options. Ensure that your selected flight controller can be easily mounted on your chosen frame and has the necessary connections for other components, such as ESCs, receivers, and telemetry modules.

By researching different flight controller options, considering the features you need, and ensuring proper mounting and connections, you can select a flight controller that meets your custom drone’s requirements.

Choosing the Right Battery

The battery is a critical component of your drone as it provides power to the motors and electronics. Consider the following when selecting a battery.

Voltage and Capacity

The battery’s voltage determines the overall power output, while the capacity affects the flight time. Strike a balance between voltage and capacity based on your desired power and flight duration requirements. Be mindful of the voltage requirements of your selected components to ensure compatibility.

Physical Size and Weight

The physical size and weight of the battery will impact your drone’s weight distribution and flight characteristics. Consider the dimensions and weight of the battery to ensure it fits and balances well on your chosen frame. A well-balanced drone will fly more efficiently and be easier to control.

Battery Safety

Prioritize battery safety by choosing reputable brands and following proper charging and usage guidelines. LiPo batteries, the most common type used in drones, can be potentially hazardous if mishandled. Ensure you have a proper charging and storage setup to minimize the risk of fire or other accidents.

By considering voltage and capacity, physical size and weight, and battery safety measures, you can select a battery that provides the necessary power while ensuring the safety of your custom drone.

Picking the Right Propellers

Propellers are essential for generating the necessary thrust to lift your drone and propel it through the air. Consider the following when selecting propellers.

Size and Pitch

The size of the propellers will affect the lifting capacity and maneuverability of your drone. Smaller propellers are generally more agile, while larger propellers can generate more thrust for heavy payloads. The pitch of the propellers refers to the angle at which the blades are positioned. Higher pitch propellers generate more thrust but may require more power. Choose propellers that match the requirements of your motors, frame, and intended use.

Material

Propellers are made from various materials, including plastic, carbon fiber, and wood. Each material has its advantages and disadvantages. Plastic propellers are affordable and lightweight but may be less durable. Carbon fiber propellers are strong and lightweight but more expensive. Wood propellers offer a classic look but can be prone to wear and moisture damage. Consider the durability, weight, and cost when selecting propellers.

Balance and Rotation

Ensure that the propellers are properly balanced to minimize vibrations and maximize performance. Imbalanced propellers can affect stability and increase wear on the motors. Additionally, ensure that the propellers are correctly installed and rotate in the intended direction based on your drone’s configuration.

By considering propeller size and pitch, material, balance, and rotation, you can select propellers that provide optimal thrust and performance for your custom drone.

Step-by-Step Assembly Process

To assemble your own custom drone, follow these general steps:

1. Frame assembly

Start by assembling the frame according to the manufacturer’s instructions. This may involve attaching arms, motor mounts, and other structural components. Ensure that all connections are secure and aligned properly.

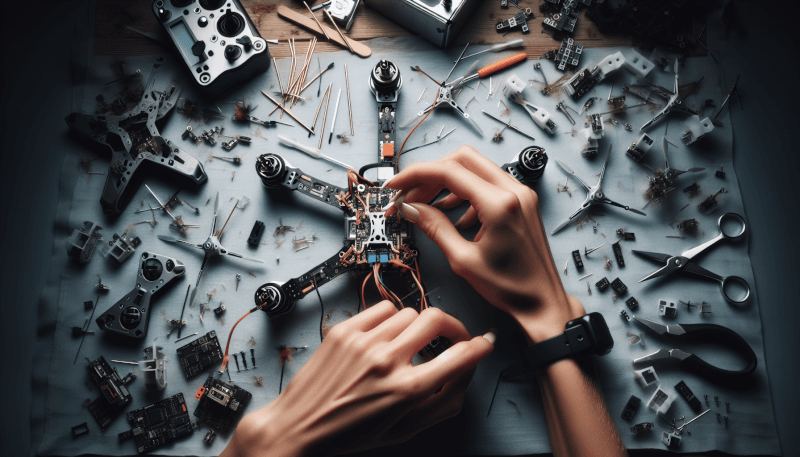

2. Motor installation

Attach the motors to the motor mounts on the frame using screws or other appropriate methods. Connect the motor wires to the ESCs, ensuring the correct wire pairing.

3. ESC setup

Mount the ESCs securely on the frame and connect them to the flight controller. Follow the manufacturer’s instructions for proper wiring and configuration. Ensure that the motor directions are correct by testing the motors individually.

4. Flight controller installation

Mount the flight controller securely on the frame, ensuring proper orientation and vibration isolation if necessary. Connect the flight controller to the ESCs, receiver, and other peripherals. Follow the manufacturer’s instructions for proper wiring and configuration.

5. Battery connection

Connect the battery to the power distribution board or directly to the ESCs, ensuring correct polarity. Securely fasten the battery to the frame, considering weight distribution and balance.

6. Propeller attachment

Attach the propellers to the motor shafts, ensuring they are properly tightened and secure. Ensure that the propellers rotate in the correct direction based on your drone’s configuration.

Throughout the assembly process, double-check all connections and ensure that everything is secure and properly aligned. Take your time and follow the manufacturer’s instructions for each component to ensure a successful assembly.

Calibrating and Testing

After assembling your custom drone, it is essential to calibrate and test its performance. Here are some steps to follow.

Sensor calibration

Calibrate the sensors on your flight controller, such as the accelerometer, gyroscope, and magnetometer. The calibration process may vary depending on your specific flight controller. Consult the manufacturer’s instructions for proper calibration procedures.

Flight controller configuration

Configure the flight controller settings, such as PID (Proportional, Integral, Derivative) tuning, flight modes, and failsafe settings. Adjust these settings to optimize the drone’s stability, responsiveness, and flight characteristics. Consult the flight controller’s user manual or online resources for guidance on configuration.

Initial flight tests

Perform initial flight tests in a safe and open area, away from people and objects. Start with basic maneuvers to ensure proper control and stability. Pay attention to any vibrations, unusual noises, or unexpected behavior. Adjust the flight controller settings or component configuration as needed.

Fine-tuning and adjustments

After the initial flight tests, fine-tune the drone’s performance by adjusting PID settings and other parameters. Make incremental changes and test in controlled flight conditions to observe the effects. Continually monitor and evaluate the drone’s performance, making necessary adjustments for optimal flight characteristics.

By calibrating the sensors, configuring the flight controller, conducting initial flight tests, and fine-tuning as needed, you can ensure a well-performing and reliable custom drone.

In conclusion, assembling your own custom drone can be a rewarding experience. By carefully selecting the right components, considering factors such as frame type, materials, and size, and following a step-by-step assembly process, you can create a drone that meets your specific goals and requirements. Remember to use the appropriate tools and follow safety guidelines throughout the process. With proper calibration, testing, and adjustments, you can fine-tune your custom drone for optimal performance and enjoy the thrilling experience of flying your creation in the skies.